Applications and good monitoring practices articles

Centrifugal Pumps

Updated at 2/24/2023

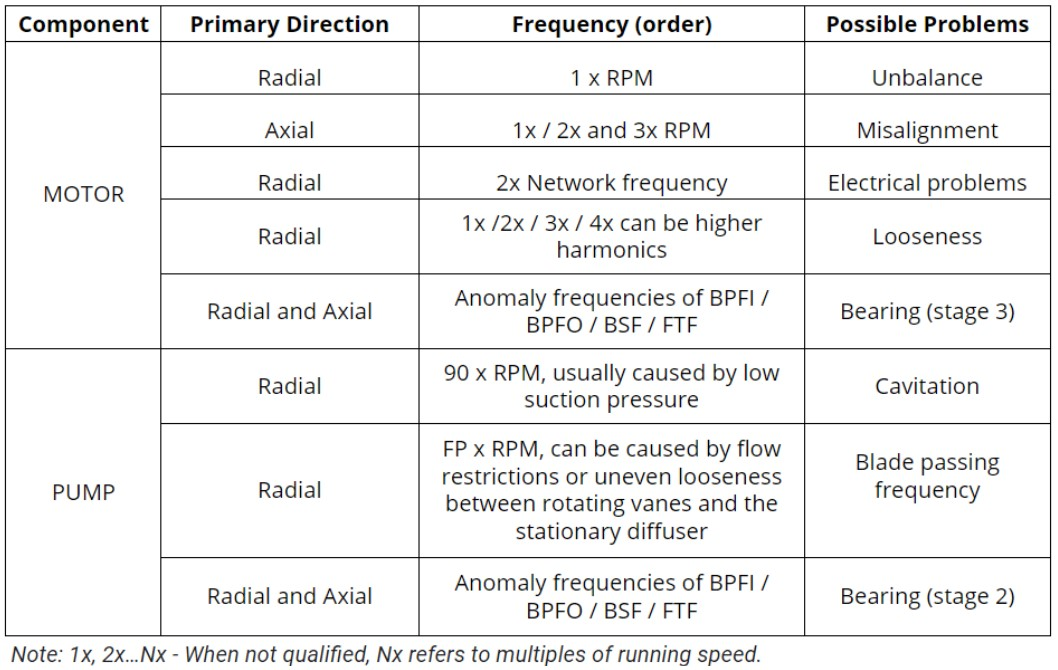

Centrifugal pumps are hydraulic machines, which consist usually of rotating elements (e.g., pump impeller, bearings, electric motor) and stationary elements (volute/casing, diffuser, stay/guide vanes, and housing bearing), which can generate fault frequencies from mechanical and hydrodynamic sources. Mechanical sources are generated by the rotation of unbalanced masses and friction in the bearings. Hydrodynamic vibration, on the other hand, is usually caused due to flow disturbances, generated by the interaction of the rotor blades, particularly with the volute and / or guide vanes.

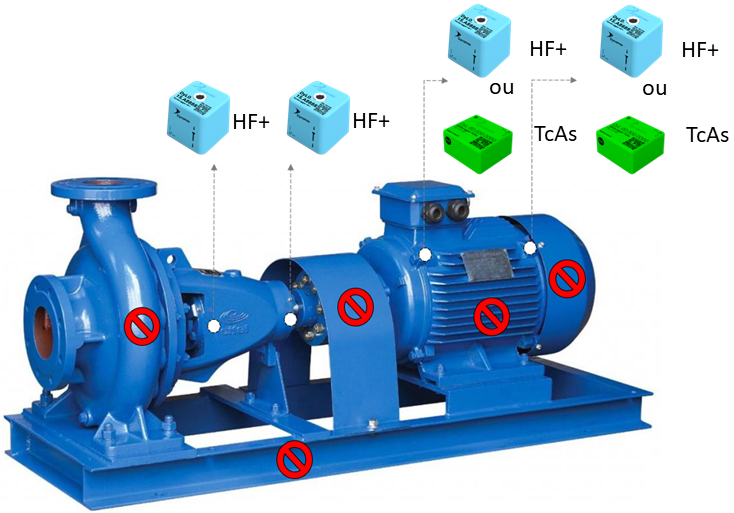

To predictively monitor the vibration and temperature parameters, two models of sensors can be used

DynaLogger HF+ and DynaLogger TcAs

The DynaLogger TcAs model can be used specifically in motors, where it will be used to identify structural defects, looseness, electrical faults and stage 3 bearing defects. In the Pump bearings, due to the faults high frequencies, the use of the DynaLogger HF+ is indicated. The number of sensors is directly linked to the number of bearings and the mechanical seal. Always try to mount the sensors as close as possible to the bearings, avoiding noisy signals and flexible parts, which can increase the reliability of the analysis.

Table 1 – Typical fault frequency and its causes

Here are pictures of actual installations of the sensors:

Back to articles